KRACHT GMBH FROM WERDOHL HAS TAKEN OVER THE PRODUCT PORTFOLIO OF 2KM GMBH FROM MARIENHEIDE AND PRESENTED THE LATEST GENERATION OF LSR DOSING SYSTEMS AT FAKUMA

2KM SilcoStar e-Flow

KRACHT SilcoStar e-Flow

KRACHT SilcoStar e-drive

South Westphalian technology company secures rights, personnel and know-how

Who is KRACHT GmbH?

The acquisition of 2KM

In July 2022, KRACHT GmbH took over important business areas of the former company 2KM GmbH (2-Komponenten Maschinenbau GmbH) based in Marienheide. This ensures that the proven 2KM product portfolio of dosing and mixing systems will continue to be available to the LSR industry.

What you can expect ...

KRACHT presented the next generation of LSR dosing systems at FAKUMA in Friedrichshafen

COMPLETELY NEWLY DEVELOPED SILCOSTAR SERIES IMPRESSES THE TRADE PUBLIC

The development of the new SilcoStar series

If you would like to know more about the new SilcoStar systems, please contact us.

The development of the new SilcoStar series

The SilcoStar 902e, 922e, 924e and e-Flow series have been known in the industry for many years for their sophisticated technology and are used in a wide range of applications. The former 2KM GmbH analyzed the special requirements of users at an early stage and recognized the need for classic, hydraulically driven and more modern, servo-electric systems. With the 9- and e-Flow series, the SilcoStars covered almost every conceivable area of application.

In the first step after the takeover, KRACHT GmbH adapted the design to be able to meet demand without interruption. At the same time, the sales department, in close cooperation with the design department, recognized that the products had a lot of potential. The idea of further developing the SilcoStar dosing and mixing systems quickly matured.

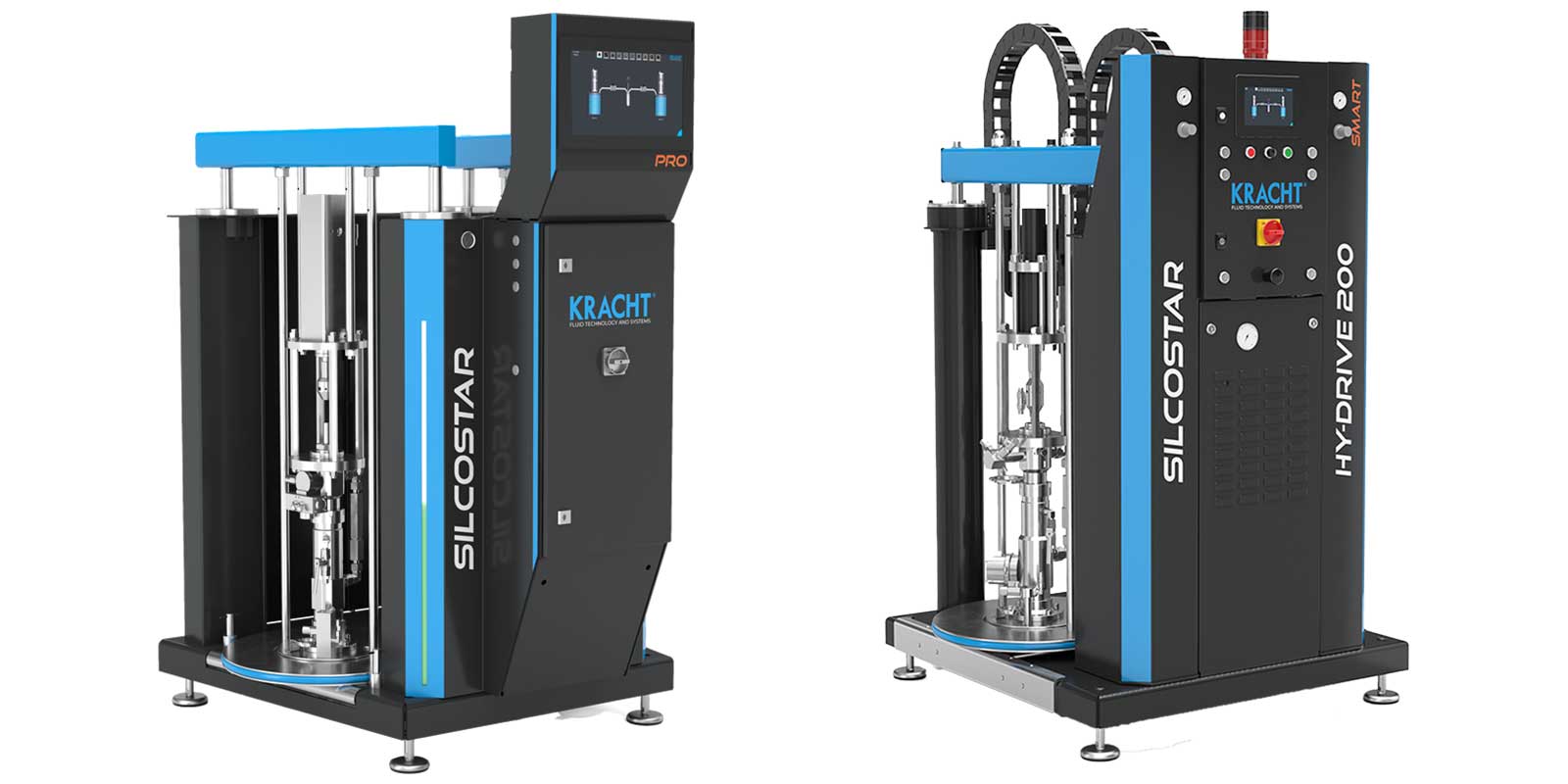

Within a year, KRACHT has developed two new series based on the existing portfolio and presented them at Fakuma. At the heart of the E-Drive series is the servo-electric linear drive with planetary roller technology, which stands for precision and durability like no other drive. For applications with a static mixing ratio, KRACHT offers the HY-Drive series with hydraulic drive. Three user interface versions – Pro, Smart and Easy – are available for the E-Drive series. The HY-Drive versions are available in Smart and Easy configurations.

If you would like to know more about the new SilcoStar systems, please contact us.

SilcoStar E-Drive

The SilcoStar E-Drive series is a servo-electrically driven dosing and mixing system for demanding tasks with a variable mixing ratio for the production of liquid silicone molded parts.

SilcoStar HY-Drive

The SilcoStar HY-Drive series is the hydraulically driven alternative for applications that only require a fixed mixing ratio (1:1).

LED barrel display

Fill level indicator with a dynamic LED strip included in the Smart and Pro versions

Electronics

- Pro - Innovative operation via 13" multi-touch display

- Smart - Modern operation via 7" multi-touch display

- Easy - Classic operation via buttons and potentiometers

Drive

The E-Drive series is characterized by its high-precision servo-electric linear drive. In addition to a long service life, this ensures consistently efficient dispensing, even with small shot weights.

New mixing head design

- Highly sensitive pressure sensor for lack of material and overpressure

- Patented mixture pressure control of mixed material

- Volumetric dosing control directly at the mixing head

- Cooling trays for static mixers

Electronics

- Smart – Modern operation via 7" multi-touch display

- Easy – Classic operation via buttons and potentiometers

Drive

New mixing head design

- Highly sensitive pressure sensor for material shortage and overpressure

- Patented mixture pressure control of mixed material

- Volumetric dosing control directly on the mixing head

SilcoStar E-Drive

The SilcoStar E-Drive series is a servo-electrically driven dosing and mixing system for demanding tasks with a variable mixing ratio for the production of liquid silicone molded parts.

The future of colour dispensing is here: Discover our exclusive E-Drive mixing head!

Revolutionise your production processes with our ground-breaking mixing head, which was specially developed for the servo-electric E-Drive models. We set new standards in terms of efficiency, cleaning and adaptability.

Why our mixing head?

Lightning-fast cleaning: Forget long downtimes for time-consuming cleaning processes. Our mixing head enables effortless cleaning in just 5 minutes – an unbeatable advantage compared to competitors.

Short downtimes: Thanks to our innovative technology, the downtimes of your production systems are significantly reduced. This means more production and less downtime.

Easy handling: The mixing head has been designed for maximum user-friendliness. Easy handling enables smooth integration into your existing processes – without time-consuming training.

Automatic adjustment: Changes in volume flow? No problem! Our mixing head automatically adjusts the colour addition to ensure the right ratio at all times. Efficiency and precision go hand in hand.

Experience the future of mixing and increase the performance of your E-Drive models. Our exclusive mixing head sets new standards for speed, efficiency and ease of use.

Contact us today and discover how our mixing head can take your production to the next level!

Worldwide top service for your company - promised!

Do you rely on 2KM systems or already trust the innovative Kracht E-Drive and HY-Drive series? Regardless of your machinery, we are there for you worldwide! Our dedicated team of experienced and competent service staff is always available to ensure that your production systems always run smoothly.

Why rely on us?

- Comprehensive support: No matter where you are in the world, we are there when you need us. Our global network enables us to provide you with a first-class technical service.

- Experts for all machines: Whether 2KM systems or the latest SilcoStar E-Drive and HY-Drive series – our service technicians are highly trained and understand the requirements of all machine types.

- Fast spare parts supply: We know how important time is. That’s why we have set up an efficient spare parts supply system to minimise downtime.

- Personal service on site: When it comes down to it, we will send an experienced service technician directly to you. Our aim is not just to solve problems, but to build long-term partnerships.

- Your satisfaction and the smooth operation of your machines are our top priority. Rely on our worldwide service and focus on what really matters – moving your business forward.

Contact us today and experience first-class technical service that knows no bounds!

Worldwide top service for your company - promised!

Why rely on us?

- Comprehensive support: No matter where you are in the world, we are there when you need us. Our global network enables us to provide you with a first-class technical service.

- Experts for all machines: Whether 2KM systems or the latest SilcoStar E-Drive and HY-Drive series – our service technicians are highly trained and understand the requirements of all machine types.

- Fast spare parts supply: We know how important time is. That’s why we have set up an efficient spare parts supply system to minimise downtime.

- Personal service on site: When it comes down to it, we will send an experienced service technician directly to you. Our aim is not just to solve problems, but to build long-term partnerships.

- Your satisfaction and the smooth operation of your machines are our top priority. Rely on our worldwide service and focus on what really matters – moving your business forward.

Contact us today and experience first-class technical service that knows no bounds!

Talk to us.

Mr. Kevin Almus

Phone +49 2392 935 296

E-Mail kevin.almus@kracht.eu

Mr. Erwin Fröse

Phone +49 2392 935 246

E-Mail erwin.froese@kracht.eu